The PDCA cycle (Plan Do Check Act) is a method that fits solving everyday problems in various spheres and activities of the company. The method originated with the need to assure quality, however, today it is being used in all lines of business.

PDCA cycle has originally been formed by Walter Shewhart in 1930. Later on, an application of the PDCA cycle for quality improvement has been used and modified by Edwards Deming.

PDCA was originally prepared for effective solution and improvement of activities, processes and systems in a production. It can be used as a simple methodology for changes implementation. Quality is the area where the cycle achieved the main development and practical usage. PDCA should be a part of knowledge of every consultant who works in the areas of quality systems, ecological systems and safety assurance.

PDCA Description

The methodology consists from the four following steps:

**P – Plan** - The cycle starts with collection of information and a description of the problem which shall be solved. It is a baseline for a plan preparation. A plan should contain activities specified as tasks what shall be done in order to solve the problem.

**D – Do** – once the plan is prepared the next step is to implement described activities.

**C – Check** – Follows achieved results monitoring and their comparison with plan. It is an inspection if an original problem was really solved.

**A – Act** – In case result differs from expectation and the problem is not solved, then look for the problem’s cause. You should focus a new plan on cause‘s elimination in such a case. If a problem is successfully dispatched than the last and final step should be to implement and standardize all needed changes into processes or system. And, as well, it should be probed if changes are correctly exercised in every day’s activities.

PDCA Usage

It is possible to use the cycle for solution on whatever either problem or changes implementation. Four basic steps of PDCA can be continually repeated. Their repetition spins the spiral of continual improvement.

The Real | Interim Manager for Your Changes

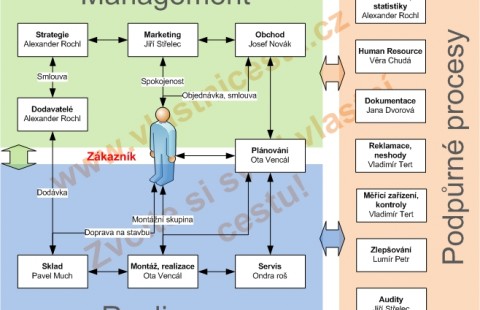

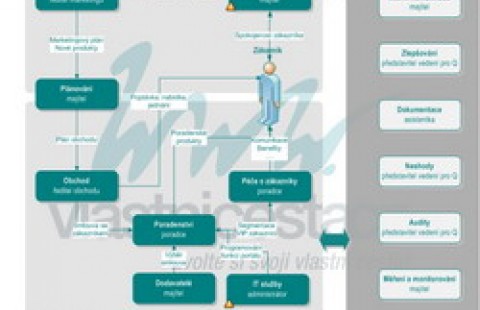

Manager work model

Time management - making use of time effectively

Jak správně tvořit mapu procesů

Modelling and setting the processes and procedures - ISO 9001

Training - preparation of the SWOT analysis and strategy

Company Management System of Quality Step by Step - ISO 9001

Process map acc ISO 9001 - business offer

IT staff communication

PDCA Applicability

PDCA is it possible to use in the following areas:

- production

- logistics

- information systems

- quality systems

- management

- marketing

- psychology

- in all areas

PDCA method is used in his every day’s work and method is described by "Jiří Střelec":http://www.ownway.eu/jstrelec/

Other consequential method is "DMAIC method":http://www.ownway.eu/academy/quality-the-quality-system/quality-quality-system-methods/the-dmaic-method/