Work productivity evaluation - one of the basic activities and one of the basic data that we use in stabilizing processes, increasing performance, planning and continuous improvement. To be able to use current real productivity data effectively, we need to make sure that we measure the right data and analyze it in the right way. Based on this data, we are able to identify related problems or even predict them. Whether on the side of machines, material supplies, workers or the working environment. We can work with data in different ways to be able to evaluate deviations from normal and abnormalities and thus find the root causes of problems.

Work productivity evaluation BEFORE process automation and data digitization

The method that is performed before the implementation of digitization and automation elements can put a lot of and unnecessary pressure on various employees across the organization. It may be related to the fact that our systems are not sufficiently agile, or they are not capable of effective communication and data sharing. Or these systems are capable of that and we just cannot use the potential that our technology offers us. The most common way of data processing, which we encounter especially in small and medium-sized prodcution companies, is based on the use of Excel spreadsheets and work with data takes place roughly in the following way:

- We collect all the necessary data and insert it manually or by exporting from the system to an Excel spreadsheet.

- We check the timeliness of the reported standards at a glance - we must think about whether nothing has changed dramatically, we do not perform revisions for this purpose.

- We copy data on reported standards to the collected data inserted in the table or export them from the system.

- When manipulating the data, we must be careful not to change anything that is preset in the Excel table, otherwise the formulas will stop working and the result will not be calculated.

- In the Excel spreadsheet, we can change anything, including how to calculate productivity or the level of compliance with the standard.

- We have to visually check and possibly correct it manually, so that everything counts as it should.

- We save the resulting table, ideally we export it to pdf, we save a copy of the table, we enter the resulting numbers into systems that continue to work with them.

At this point, we need to realize that it is necessary for the foreman in production to process the data in an Excel spreadsheet and at the same time be able to keep different copies and versions of the spreadsheet and solve problems when copying new data. The administrative burden of his work thus increases and at the same time it is not possible to use the results in real time, because people are not able to process it so quickly. The tables can usually be intervened by a larger number of employees, such as the foreman of each shift, the technologist, etc. This can lead to unwanted adjustments at the level of data and formulas. We also encounter the fact that the data is purposefully manipulated, or due to ignorance or unwillingness to cooperate, meaningless data are entered. In addition to these factors, it is also important to mention that people who devote their time to this way of processing data for their own needs and the company in general, spend time on activities that they would not have to perform at all and could gain space to work with their teams. In terms of motivating their people, improving processes, finding the causes of problems and eliminating them.

Work productivity evaluation with use of process automation and data digitization

Digitization of our data, interconnection of systems and technologies that we use and automation of part or the whole process will allow us to cope with all the shortcomings that come with manual data processing. The biggest advantage here remains the ability to monitor current real data and identify various abnormalities and problems that are occurring in production or even predict them. The first step we need to take to automate productivity assessments is to record all the categories of data we will need to calculate and verify how good this data is and where it can be collected. To evaluate productivity, we will definitely need:

- list of all products

- production process

- operation times

- preparation times

- established standard for workers and possible time surcharges

- real reported time and production volume

- reported quality / poor quality pieces

- attendance information

- other specific data according to the type of production and the exact purpose of processing

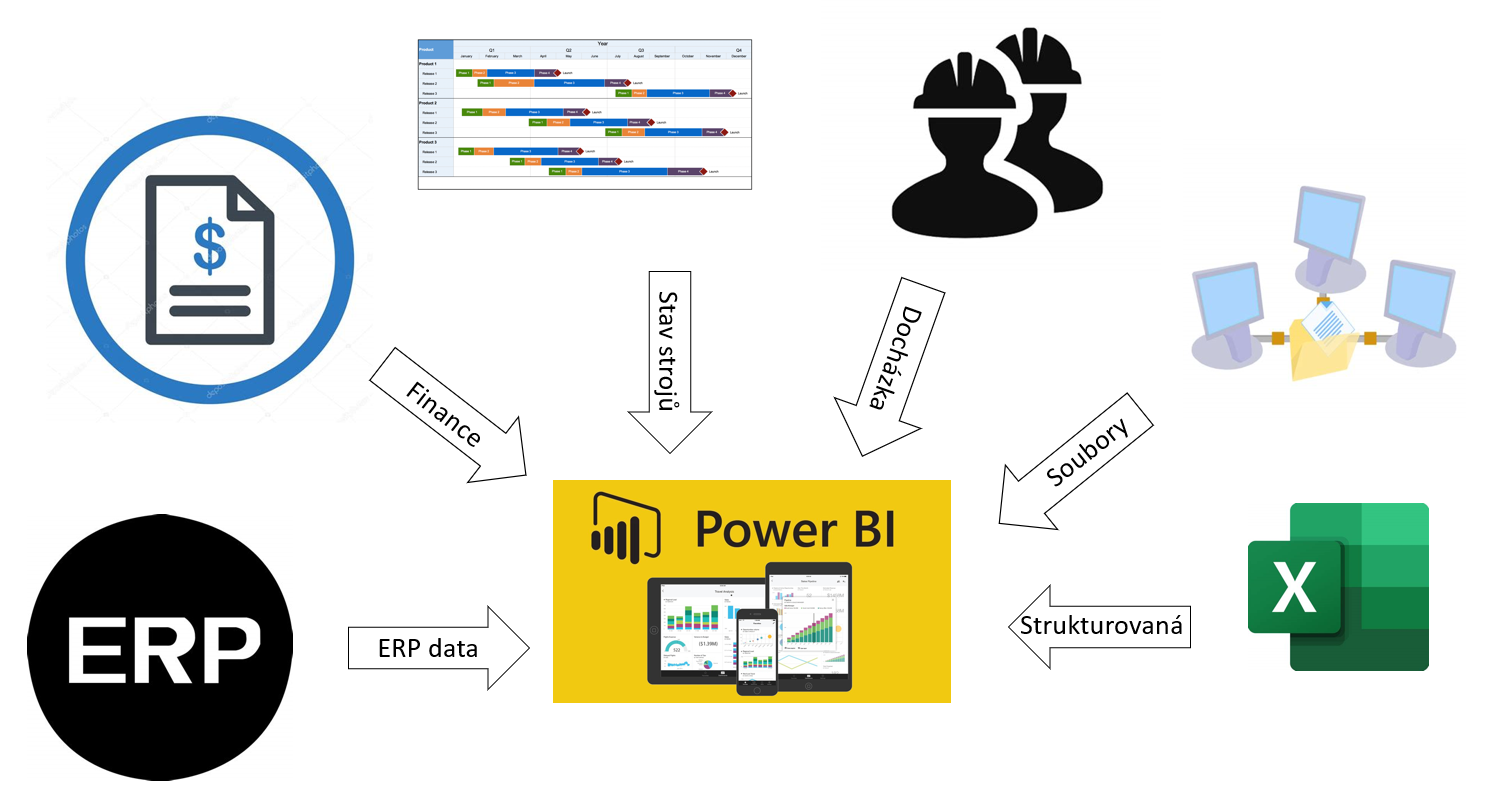

This information is most often found in the ERP system, the production monitoring system, the system or documents for production reporting, the attendance system, shared tables and, of course, in some cases it can also be manual records. We must first digitize all the necessary data, ideally use existing available technologies, or purchase new technology. For automation, it is necessary to load all the necessary data in one environment and set or program the analytical steps that the system should perform in order to be able to present the required and current results. One of the most suitable solutions today for such a very flexible and adaptable approach is Power BI.

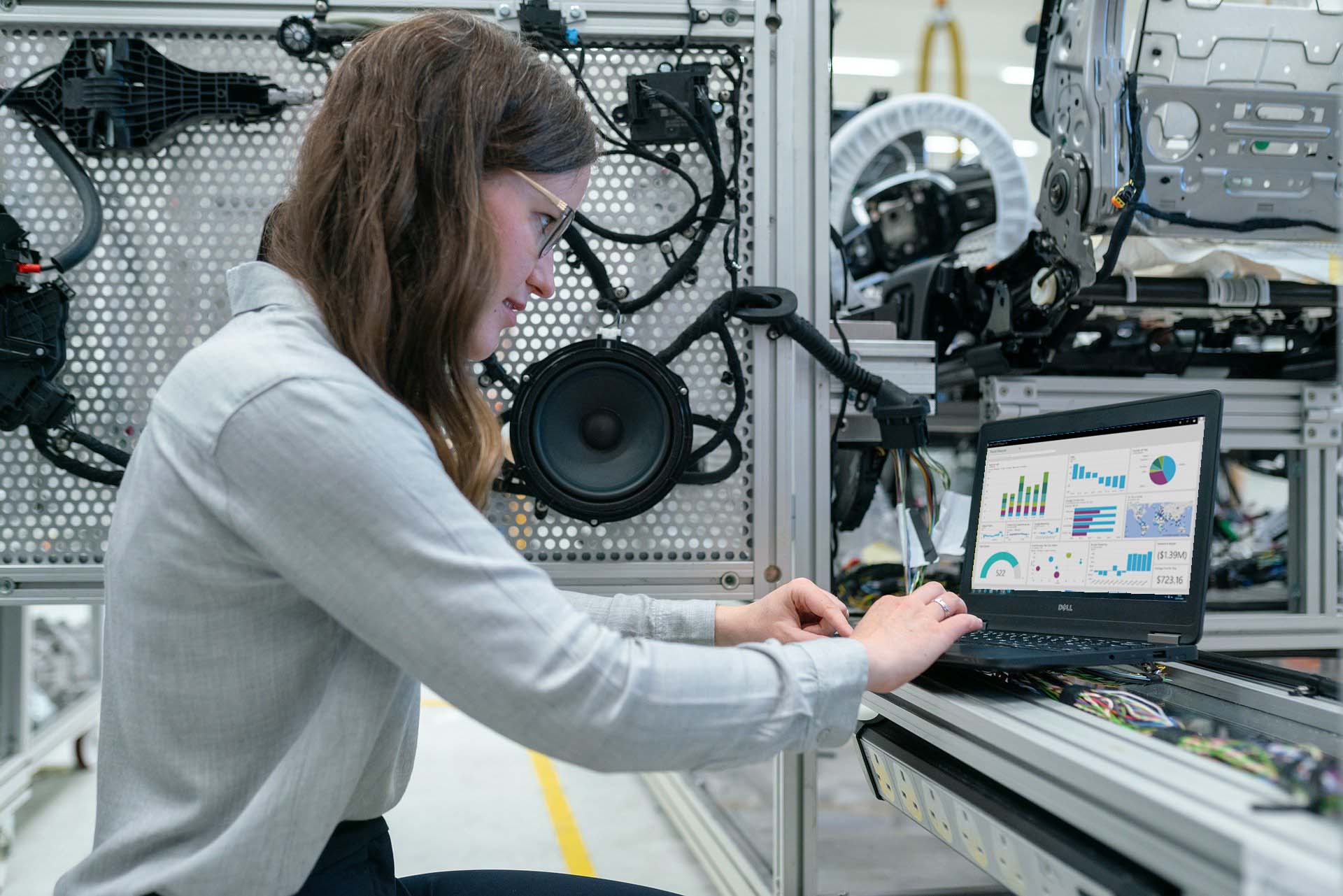

The basic requirement for an automated solution is that it is reliable and that everyone across the company can trust it. For this reason, it is essential to be sure of the quality of the input data and their importance for the resulting information, with which we continue to work and on the basis of which we make decisions. This is the only way to compile a quality, sustainable and personalized report. Thanks to the diversity of data and their relationships, we can then go through various details in a well-processed digital report, of which the results consist exactly according to what we are specifically interested in, or where we could identify the causes of problems. A typical example is dealing with extremely low productivity over a period of time, such as a week. After clicking on the selected week, details will be displayed at the level of individual days, machines, products or people, depending on which view we prefer. Based on this detail, we can dedicate our time to discovering the cause of why productivity in a given period does not reach the set goal. We primarily deal with eliminating the causes of problems, improving and working with people, not collecting and analyzing data needed for decision-making.

BENEFITS OF PROCESS DIGITALIZATION

The main benefits of data digitization and process automation in evaluating productivity and other key performance indicators and metrics are:

- We work with a realistic view of processes, no one has the opportunity to influence the results, or only precisely specified people in specified ways.

- Updating data and displaying results is very reliable.

- We can easily analyze various details, look for the causes of problems and achieve our goals.

- The administrative burden on employees is declining dramatically, especially in the production of foremen, but also of middle and senior management.

- The reports show each person a view that is useful to him and serves him to make effective decisions.

- We see in real time the effects of improvement activities or various implemented changes.

- We use the full potential of our systems.

- People do not have to perform routine tasks, it is more to use their potential in the form of knowledge and skills.

We wish you great success in digitization and automation of your business processes!